Print-Apply Systems

Having the flexibility to print your own labels at any time is already very important, but being able to print and apply the labels automatically and with high precision will make all the difference, reducing costs and increasing your productivity to whole new levels. The print and apply systems from Weber® are very robust, reliable and compact, combining a high resolution direct-/thermal-transfer label printer with an automatic applicator, in order to, in one go, print and apply labels on top, below, in front/rear and/or on the sides of products or in the product's corners. The application is done directly on the conveyor, usually without stops. There are multiple application methods available, such as the classic application arm with a tamp to press the label onto the product or the contactless method that blows the label from a small distance away.

- Compatible with Printer Modules from Zebra®, Datamax®, Sato®, Novexx® and Avery®

- Extremely precise placement of the labels with error margins inferior to 1mm

- Very high speeds and application rates

- Reduces labor costs and assures a fast, efficient and productive labeling

- Different application methods so that the system can perfectly adapt to your products

- 1:1 consumption so that you change the print ribbon and the label roll at the same time

- Adjustable stands to fit the system in your production line

- Just in time label printing to solve the problem of obsolete or outdated pre-printed labels

- Easy integration

- And much more...

-

Legi-Air 5300 ▶︎

Print-Apply SystemDifferent Applicators

RH or LH Versions -

Legi-Air 4050E Gen3 ▶︎

Print-Apply SystemDifferent Applicators

RH or LH Versions -

Legi-Air 4050 Gen2 ▶︎

Print-Apply SystemDifferent Applicators

RH or LH Versions -

Legi-Air 4050B ▶︎

Print-Apply SystemDifferent Electric Applicators

RH or LH Versions -

Legi-Air 4050CWB ▶︎

Print-Apply SystemCorner-Wrap Applicator

RH or LH Versions -

Legi-Air 4050AC Gen2.1 ▶︎

Print-Apply SystemWipe-On Applicator w/ Accumulator

RH or LH Versions -

Legi-Air 4050I Gen2 ▶︎

Print-Apply SystemDifferent Applicators (in Cabinet)

RH or LH Versions -

Legi-Air 6000 ▶︎

Print-Apply SystemTamp-Blow

RH or LH Versions -

Legi-Air 2050 ▶︎

Print-Apply SystemTamp-Blow

LH Version -

Geset 141-P ▶︎

Print-Apply SystemSemi-Automatic Wrap-Around

LH Version

Notes about the Models:

-

Model 6000

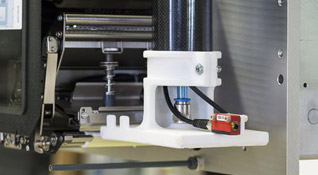

Print-and-apply system with a long and high-speed applicator arm, perfect for labeling products with varying heights. The unbelievable speed that the system can reach is due to a powerful servo motor and the construction of the movable parts and application tamp with light materials such as carbon fiber. Thus, we have a light and fast applicator that maintains a high resistance and durability. With application rates that reach 2400 products per hour. -

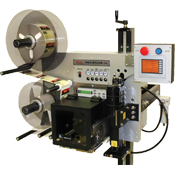

Model 5300

American designed print-and-apply system that has a very robust construction but still, has a very appealing look. A model that is at the top of the range when it comes to print-and-apply systems, for the most demanding customers. -

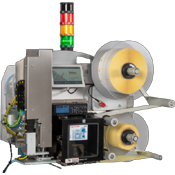

Model 4050E

Print-and-apply system made in German that has gained immense popularity in the market and has proven itself worthy. The "E" means Enhanced, it has a big color touch-screen and is available with many versions of tamp applicators. -

Model 4050B

"B" that stands for "Be Safe, Be Fast, Be Fit, Be Electric". There are 4 types of applicators, all of them electric. The movement of the applicator arm is powered by electric motors instead of air pressure for maximum speed and precision. One of the 4 versions is 100% electric, not requiring a compressed-air connection. For the other versions, the compressed-air is only used to hold the label and blow it to the product without any contact whatsoever, but even so, the compressed-air consumption can be cut up to 80%. -

Model 4050CWB

Version of the 4050 model for corner-wrapping applications on boxes. -

Models 4050WO and 4050AC

Versions of the 4050 model that use the Wipe-On application method, which does not require compressed-air. The 4050AC has a printed label accumulator to allow short application bursts at high-speeds. -

Model 4050I

Version of the 4050 model that is inside a protective cabinet for usage in dusty or other difficult environments. -

Model 2050

A tamp applicator is coupled to the popular Sato® printer, the CL4NX. The synchronization is done with a cable that is connected to the printer's back. -

Geset 141-P

An Epson® printer is used to print high-quality color labels and is connected to a semi-automatic applicator (with manual product feeding) to allow the print and application of labels on bottles, cans and other cylindric objects.

-

Legi-Air AP182 ▶︎

Print-Apply SystemPallet Applicator (3 sides)

RH or LH Versions -

Legi-Air 5300 Pallet ▶︎

Print-Apply SystemPallet Applicator (1 side)

RH or LH Versions -

Legi-Air 5300 Dual Pallet ▶︎

Print-Apply SystemPallet Applicator (2 sides)

RH or LH Versions -

Legi-Air 4050P ▶︎

Print-Apply SystemDifferent Pallet Applicators (1 or 2 sides)

RH or LH Versions

Notes about the Models:

-

AP182

A 3-axis print-and-apply system to allow the application of labels in 3 sides of the same pallet in one passage. -

5300 Pallet / Dual Pallet

A print-and-apply system based on the model 5300 with a longer and reinforced arm for pallet application. The Dual version allows the application in 2 sides of the same pallet. -

4050P

A print-and-apply system based on the model 4050 with special applicators for pallet application. There are several versions available, such as the 4050P2A or 4050PL2A to apply labels in 2 sides of the same pallet.